Woodworking has evolved significantly over the years, with tool innovations making it easier for craftsmen to achieve professional-quality finishes. Among these innovations, cutterhead technology stands out for its impact on the final product. Two designs—helical and spiral—are particularly popular among woodworkers seeking smoother finishes and greater efficiency. Understanding the differences between these cutterheads is crucial for making an informed upgrade decision.

Why Cutterhead Design Matters

The cutterhead is the heart of a planer or jointer, determining how efficiently and cleanly it cuts wood. A poorly designed cutterhead can result in tear-out, uneven surfaces, and excessive noise. Conversely, a high-quality cutterhead can make even difficult woods smooth to the touch while minimizing post-planing sanding. This is why woodworkers often consider upgrading to either a helical or spiral cutterhead, both of which outperform traditional straight knives.

Understanding the Helical Cutterhead

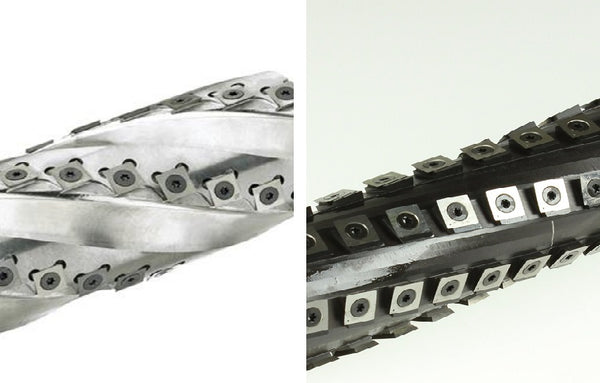

A helical cutterhead features rows of small, square carbide inserts arranged in a spiral pattern, with each insert set at a slight angle to the wood grain. This angled cutting action shears the wood fibers rather than chopping them, resulting in a cleaner, quieter cut. Helical cutterheads are also known for their durability, as carbide inserts can last much longer than traditional steel knives.

Exploring the Spiral Cutterhead

The spiral cutterhead is similar to the helical design in that it also features multiple carbide inserts arranged in a spiral pattern. However, the inserts in a spiral cutterhead may not always be angled, meaning the cutting action is slightly different. While still superior to straight knives, spiral cutterheads may produce a slightly different surface finish compared to their helical counterparts.

Helical vs Spiral Cutterhead: Key Differences

The primary difference between the two lies in the orientation of the cutting inserts. Helical designs use angled inserts to slice wood fibers, while spiral designs use straight-mounted inserts in a spiral pattern. This subtle change affects cut smoothness, noise levels, and chip removal efficiency. In general, helical cutterheads offer the quietest operation and the smoothest finish, while spiral cutterheads still offer significant improvements over straight knives at a potentially lower cost.

When deciding between helical vs spiral cutterhead, it’s worth considering specific models like the helical vs spiral cutterhead upgrade for the DeWalt 13” Planer, which is designed to improve cutting precision and reduce tear-out even on challenging wood grains.

Benefits of Upgrading from Straight Knives

Regardless of whether you choose helical or spiral, the jump from traditional straight knives is substantial. Both designs offer better surface finishes, reduced tear-out, and quieter operation. Additionally, the segmented cutting approach reduces strain on the motor, potentially extending the life of the planer or jointer. The ease of replacing or rotating individual inserts also means less downtime and lower maintenance costs.

Choosing the Right Cutterhead for Your Needs

Your choice between helical and spiral cutterheads should depend on the type of work you do, the materials you work with, and your budget. If you frequently work with highly figured or exotic hardwoods, a helical cutterhead may offer better results. If you’re looking for a cost-effective upgrade that still delivers a significant improvement over straight knives, a spiral cutterhead could be a great choice.

Maintenance Tips for Long-Lasting Performance

Proper maintenance will keep your cutterhead performing at its best. Keep the planer or jointer bed clean and lubricated to prevent friction. Rotate carbide inserts periodically to expose fresh cutting edges. Inspect the inserts regularly for damage and replace them as needed. Using a quality dust collection system will also help prevent chips and dust from interfering with cutting performance.

Safety Considerations When Working with Cutterheads

Safety should always come first when working with power tools. Always wear safety glasses and hearing protection when operating a planer or jointer. Avoid wearing loose clothing, and keep your hands a safe distance from the cutterhead during operation. Before making any adjustments or replacing inserts, ensure the machine is completely powered off and unplugged.

Final Thoughts on Helical and Spiral Cutterheads

Both helical and spiral cutterheads represent a significant leap forward from traditional straight knives. While the helical design typically offers superior cut quality and quieter operation, spiral cutterheads are still an excellent choice for woodworkers seeking performance and efficiency. By carefully considering your woodworking needs, budget, and the type of materials you work with most often, you can choose the cutterhead that best suits your workshop and enjoy cleaner, smoother results in all your projects.